In compliance with EU personal data protection laws, we are committed to protecting and providing you with control over your personal data.

By clicking "Accept All", you allow us to place cookies to enhance your experience on this site, help us analyze site performance and usage, and enable us to deliver relevant marketing content. You can manage your cookie settings below. By clicking "Confirm" you agree to the current settings.

NdFeB

NdFeB magnet is currently the strongest magnet among various magnet materials. There are four main indicators to measure the performance of sintered NdFeB products.

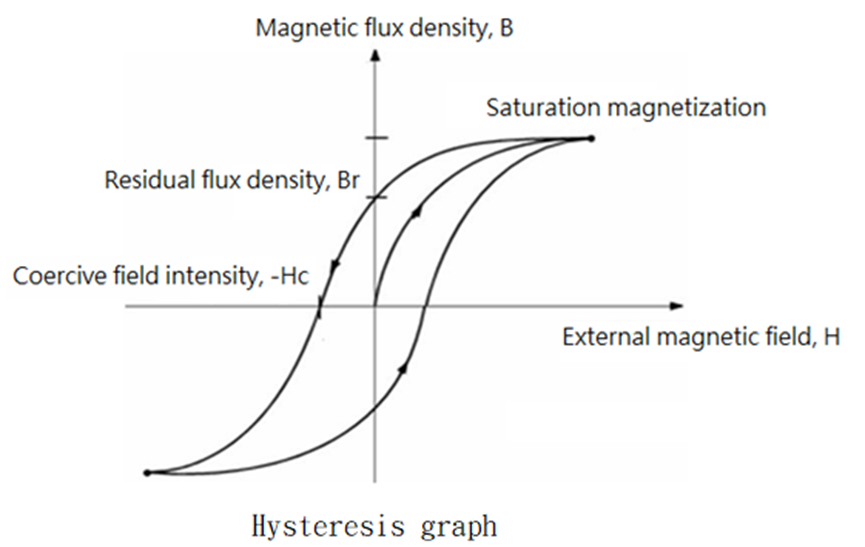

- Residual flux density, Br:The units are Tesla (T) and Gauss (Gs), 1Gs =0.0001T. It refers to the magnetic induction intensity displayed by the sintered NdFeB magnet when a magnet is magnetized by an external magnetic field in a closed circuit environment to technical saturation and then the external magnetic field is removed. In layman's terms, it can be temporarily understood as the magnetic force of the magnet after magnetization.

- Coercivity Hcb:The unit is Oersted (Oe) or A/m (A/m), 1A/m=79.6Oe. When the magnet is reversely magnetized, the value of the reverse magnetic field intensity required to reduce the magnetic induction intensity to zero is called the magnetic induction coercivity. However, the magnetization intensity of the magnet is not zero at this time, but the applied reverse magnetic field and the magnetization intensity of the magnet cancel each other out. If the external magnetic field is removed at this time, the magnet still has certain magnetic properties.

- Intrinsic Coercive Force Hcj:The strength of the reverse magnetic field required to reduce the magnetization of a magnet to zero is called intrinsic coercive force, and its measurement unit is the same as coercive force. The classification of magnetic material grades is based on the size of their intrinsic coercive force. Low coercivity N, medium coercivity M, high coercivity H, ultra high coercivity UH, extremely high coercivity EH, and high coercivity TH. The intrinsic coercivity of NdFeB magnets will decrease as the temperature increases, and the maximum operating temperature that different brands can withstand is different. Therefore, when choosing to use NdFeB magnets, be sure to choose the one that is suitable for use. brand number.

- Max.Energy Product (BH)max:It represents the magnetic energy density established in the two magnetic pole spaces of the magnet, that is, the static magnetic energy per unit volume of the air gap. It is the maximum value of the product of Br and Hcj. Its size directly indicates the performance of the magnet. The number in the magnetic material grade represents the theoretical maximum magnetic energy product of the product.

NdFeB magnets on the market are divided into various grades, such as N42N, 38UH, and N42SH. Magnets of different strengths are distinguished by grade. The symbols in magnet grades are explained as follows:

N xx o

1. The letter N in front of the grade represents neodymium. All NdFeB magnet grades begin with N.

2. The xx part of the grade is represented by a number, which represents the maximum magnetic energy product of the magnet (unit: MGOe). The larger the number, the stronger the magnetic field provided by the magnet.

3. The o part in the grade is represented by an English letter or a blank, indicating the maximum operating temperature of the magnet before it loses its magnetism.

The order of magnet temperature resistance from high temperature to low temperature is AH, GH, EH, VH, UH, TH, SH, H, M and finally blank. The highest temperature resistance AH can reach 230°C, and the lowest temperature resistance is 80°C.

The following table shows the common magnet grades corresponding to their maximum operating temperatures.

|

Magnet grade |

Maximum operating temperature |

Magnet grade |

Maximum operating temperature |

|

N52 |

80°C |

N42UH |

180°C |

|

N50 |

80°C |

N40UH |

180°C |

|

N48 |

80°C |

N38UH |

180°C |

|

N50M |

100°C |

N40VH |

190°C |

|

N48M |

100°C |

N38VH |

190°C |

|

N45M |

100°C |

N35VH |

190°C |

|

N50H |

120°C |

N38EH |

200°C |

|

N48H |

120°C |

N35EH |

200°C |

|

N45H |

120°C |

N33EH |

200°C |

|

N45SH |

150°C |

N35GH |

210°C |

|

N42SH |

150°C |

N33GH |

210°C |

|

N40SH |

150°C |

N30GH |

210°C |

|

N44TH |

160°C |

N33AH |

230°C |

|

N42TH |

160°C |

N30AH |

230°C |

|

N40TH |

160°C |

N28AH |

230°C |